Thanks to its long-standing experience and its ongoing staff training approach, Meccanica Reguzzo is capable of taking on any kind of complex machining order.

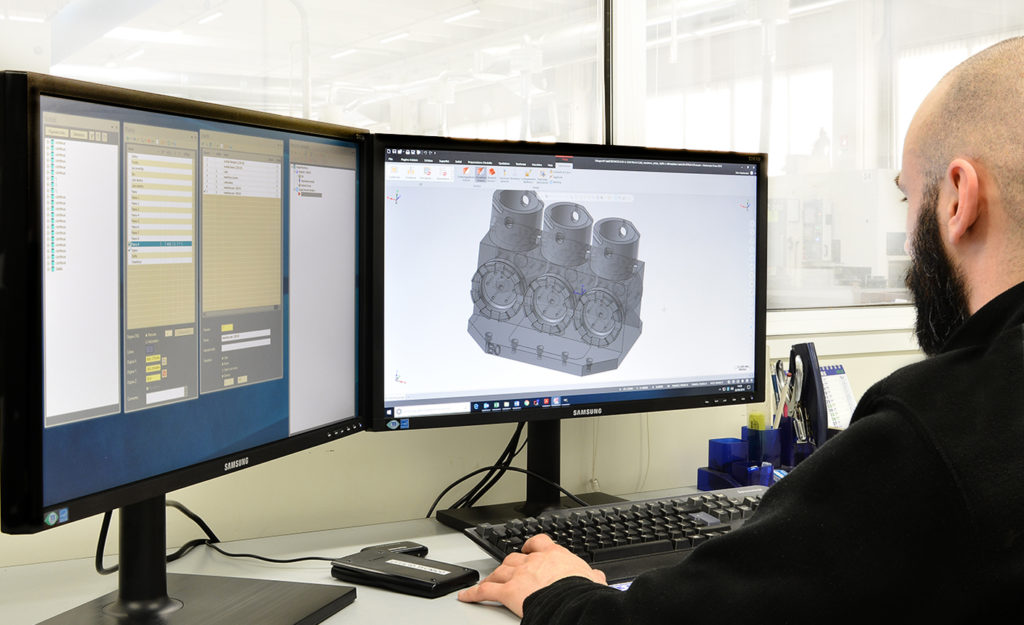

3D design projects are carried out using CAD/CAM workstations so as to ensure the optimal production of every single piece machined in our plant. Thanks to the use of specialised software, we can guarantee excellent timing and processing.

We perform CNC and Reverse Engineering processes.

OUR MACHINERY

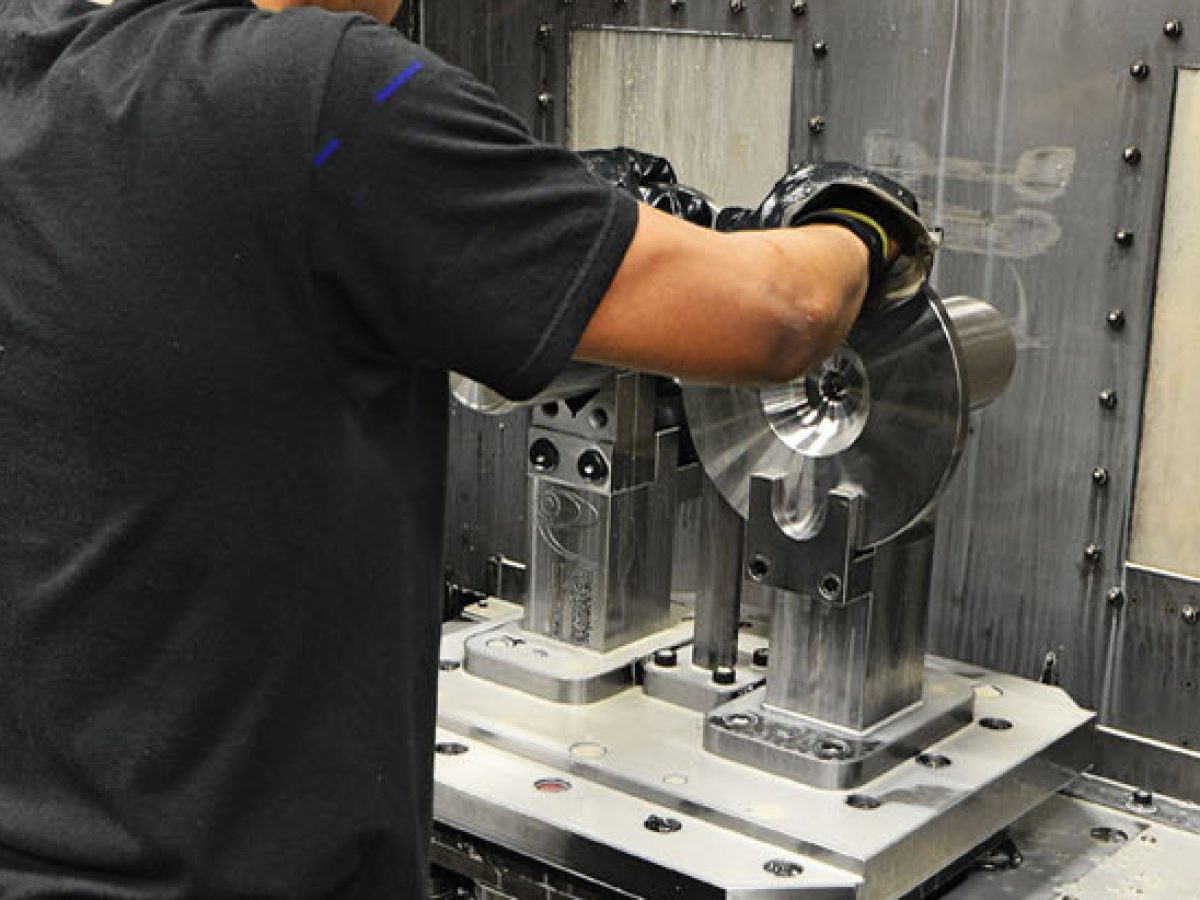

MACHINING CENTRES

Mori Seiki Horizontal Multipallet Machining Centres

Machining axis: X axis 630 mm – Y axis 600 mm – Z axis 670 mm

∅ of position inversion in the machine 730 mm

Max piece height 900

Rotary table 360 divisions

Spindle speed 14,000 g/min

Cartridge capacity 140 tools

ISO 40 two pallets measuring 500×500

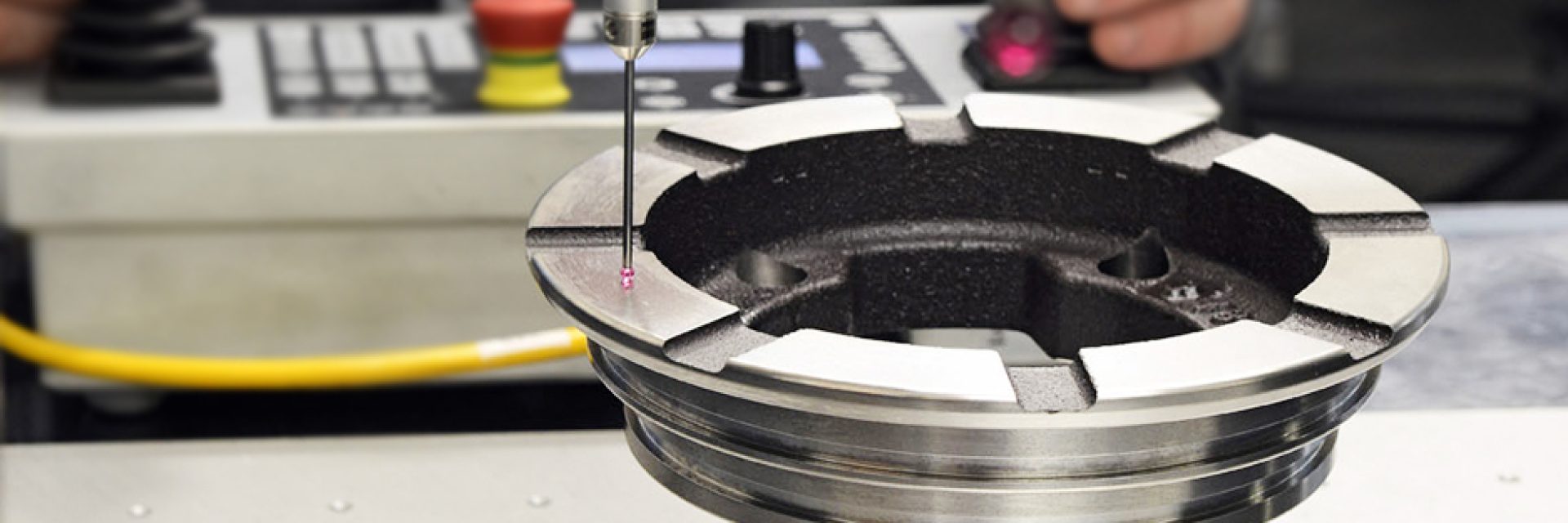

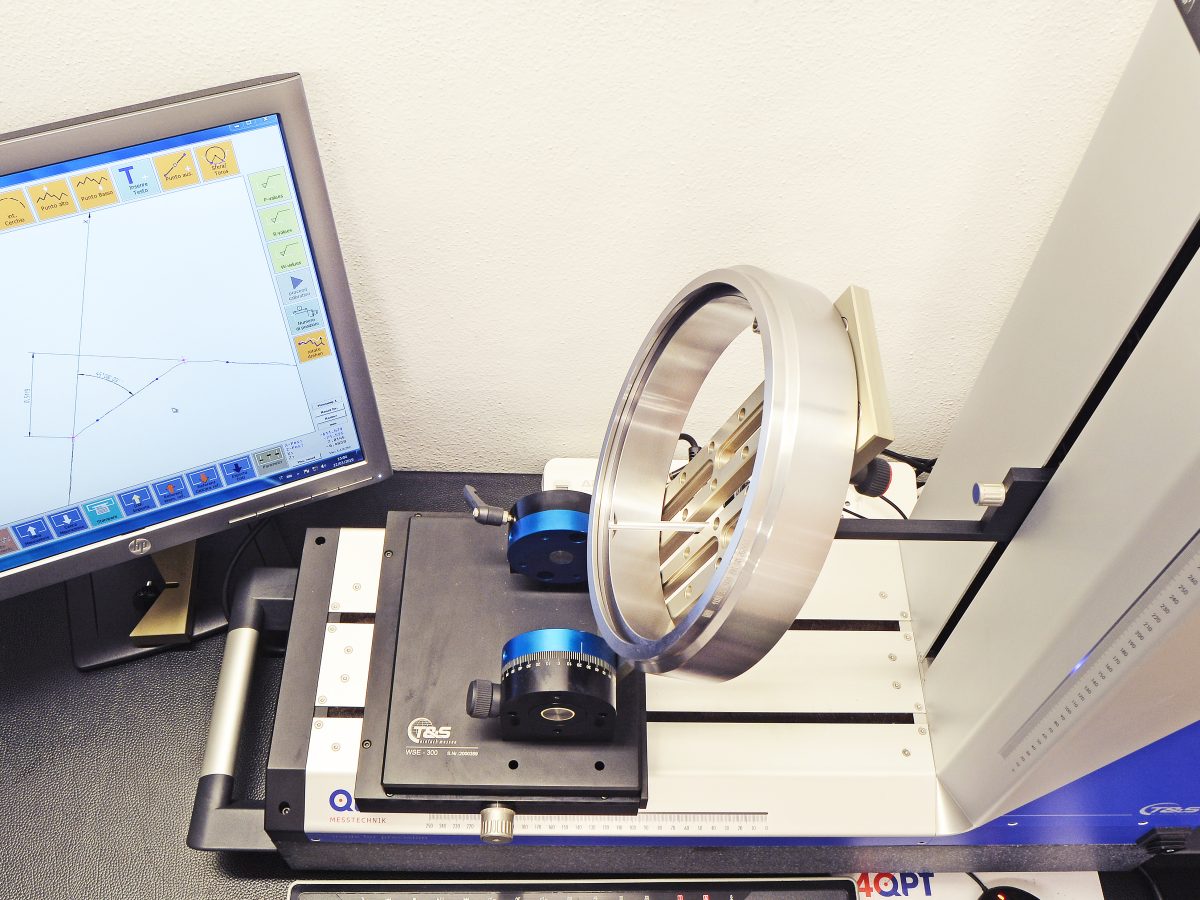

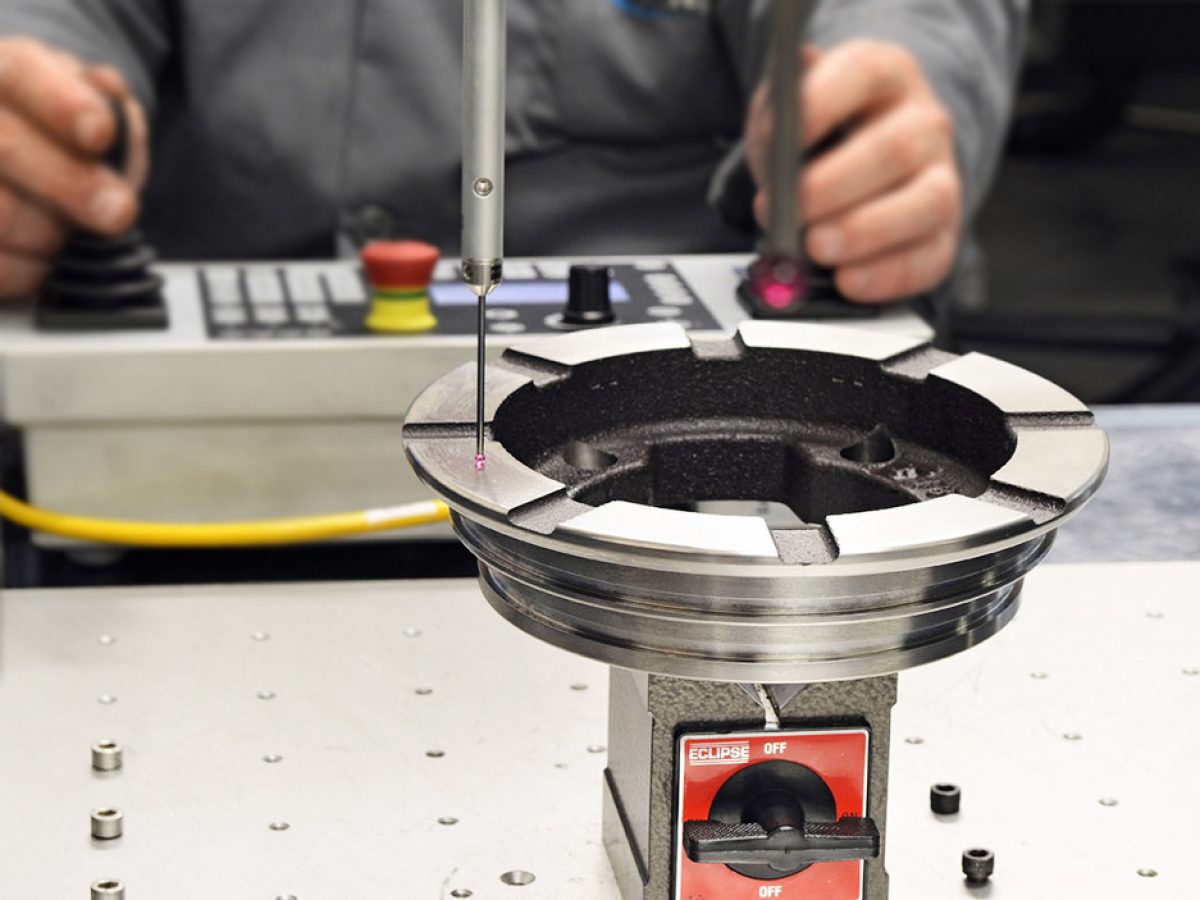

METROLOGY ROOM

We have an air-conditioned metrology room equipped with a 3D ZEISS CMM machine and a 3D DEA machine, with which we can perform sample or single piece statistic controls, with related issue of inspection certificates.

VERTICAL PICK-UP LATHES

max turnable ∅ 400

Motor-driven tools

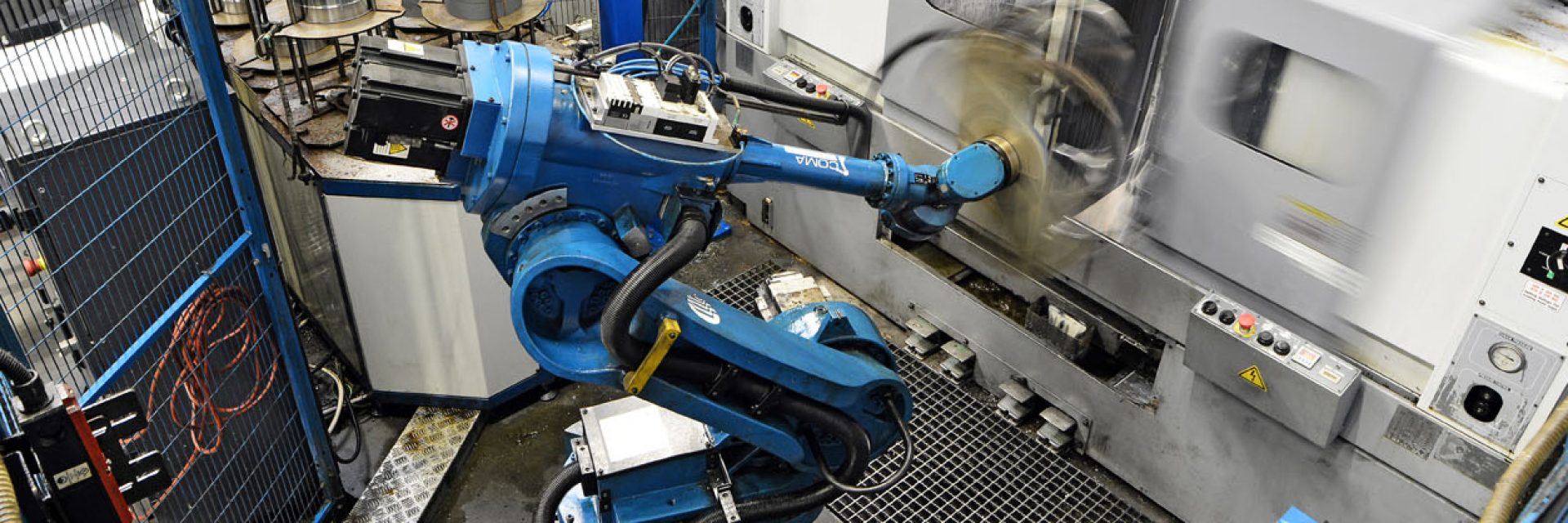

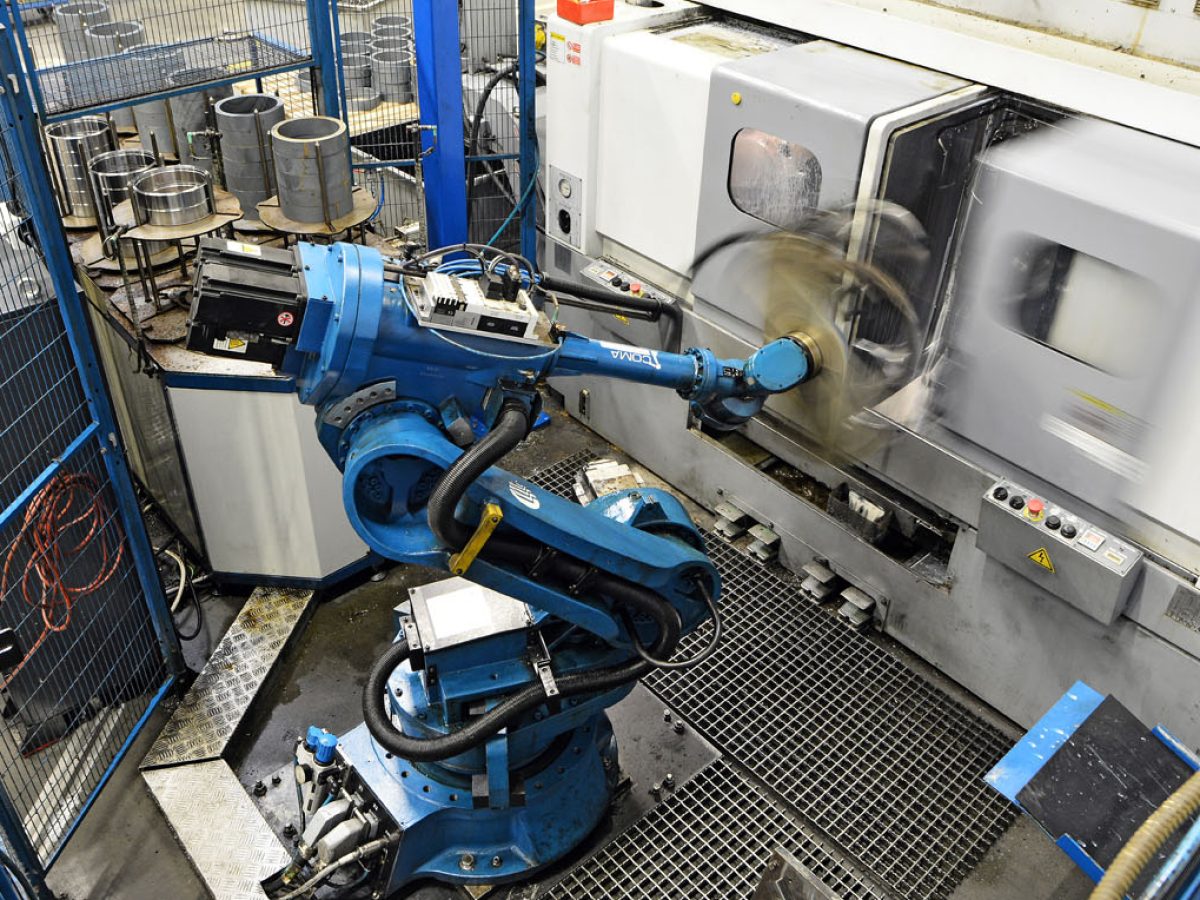

DOUBLE-SPINDLE ROOM WITH ROBOT

max turnable ∅ 350

for medium/large production batches

STORAGE AND LOGISTICS

We have an automated warehouse that automatically handles and re-orders consumables.

The surface area for finished product storage and warehousing amounts to 1000 m2.

Our efficient logistic system provides for fast and punctual delivery.