Meccanica Reguzzo has been working in the special field of CNC turning and milling for the last twenty-five years.

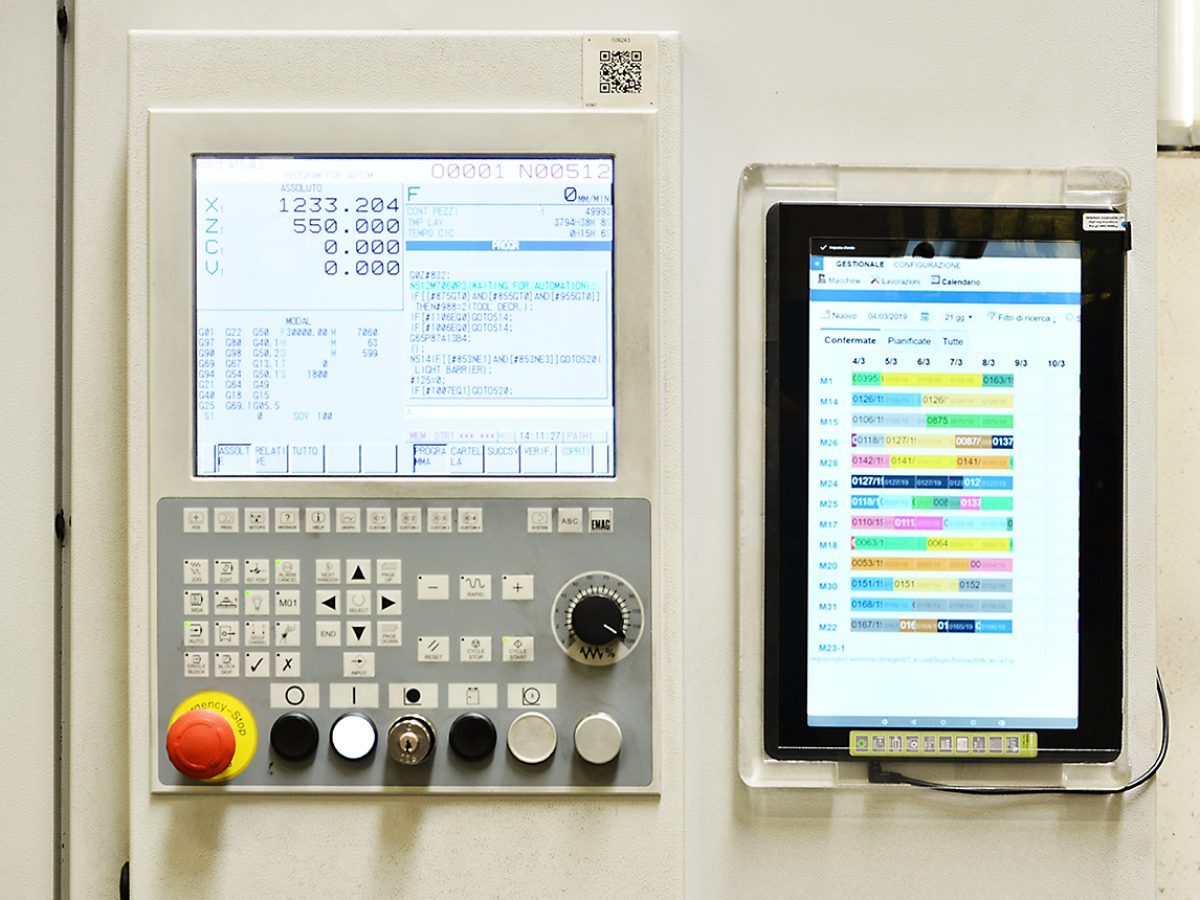

All machining processes are performed in the company’s plant using numeric control tool machines and automated processing stations. Our machine pool ranges from 4th axis machining centres with 2-6 pallets, front and vertical single-spindle and double-spindle lathes served by servo-robots for a maximum turnable diameter of 450 mm. Overall weight from 0.40 to 30 Kg.

The processing technologies and the equipment used are all state of the art and continuously evolving. This approach, together with our great flexibility, make Meccanica Reguzzo capable of producing a wide range of very high quality products at competitive prices: from simple machined components to the more complex items destined for the automotive industry, farming machinery, gearboxes for earth moving and petro-chemical equipment.

Our clientele consists of national and international enterprises.

Our current job orders vary from 100 item lots up to lots of 30,000 and more pieces. Quality control is performed using a ZEISS measurement machine, a three-dimensional CMM measurement machine and certified instruments thanks to which we can ensure precise checks on each single item.

Our company holds UNI EN ISO 9001:2008 certification obtained through BSI.